Capacity planning should be straightforward. Comparing incoming work against available resources – that’s all there is to it, right? But any Aussie manufacturer or cabinetmaker who has tried to manage capacity for a growing manufacturing business knows how quickly things get complex.

Jobman automates capacity planning for manufacturing, ensuring accurate, balanced scheduling across the production process. With Jobman, you can go a step further than simply scheduling to fill available space. You can optimise capacity planning for maximum productivity, minimal downtime and no unexpected overtime.

Automated capacity planning improves productivity, saves time and reduces costs. It also helps to reduce bottlenecks, giving manufacturers and cabinetmakers more capacity to grow the business.

All in all, intelligent capacity planning is one ERP feature you can’t afford to overlook.

Benefits of Jobman’s Capacity Planning Software

- Saves hours on capacity planning

- Accurate job scheduling

- Optimises your available resources

- Streamlines drafting and production

- Reduces overtime costs

- Helps to eliminate bottlenecks

- Flexible browser-based software can be accessed anywhere

- Easy to use

- Adaptable calendar view

- You set the parameters

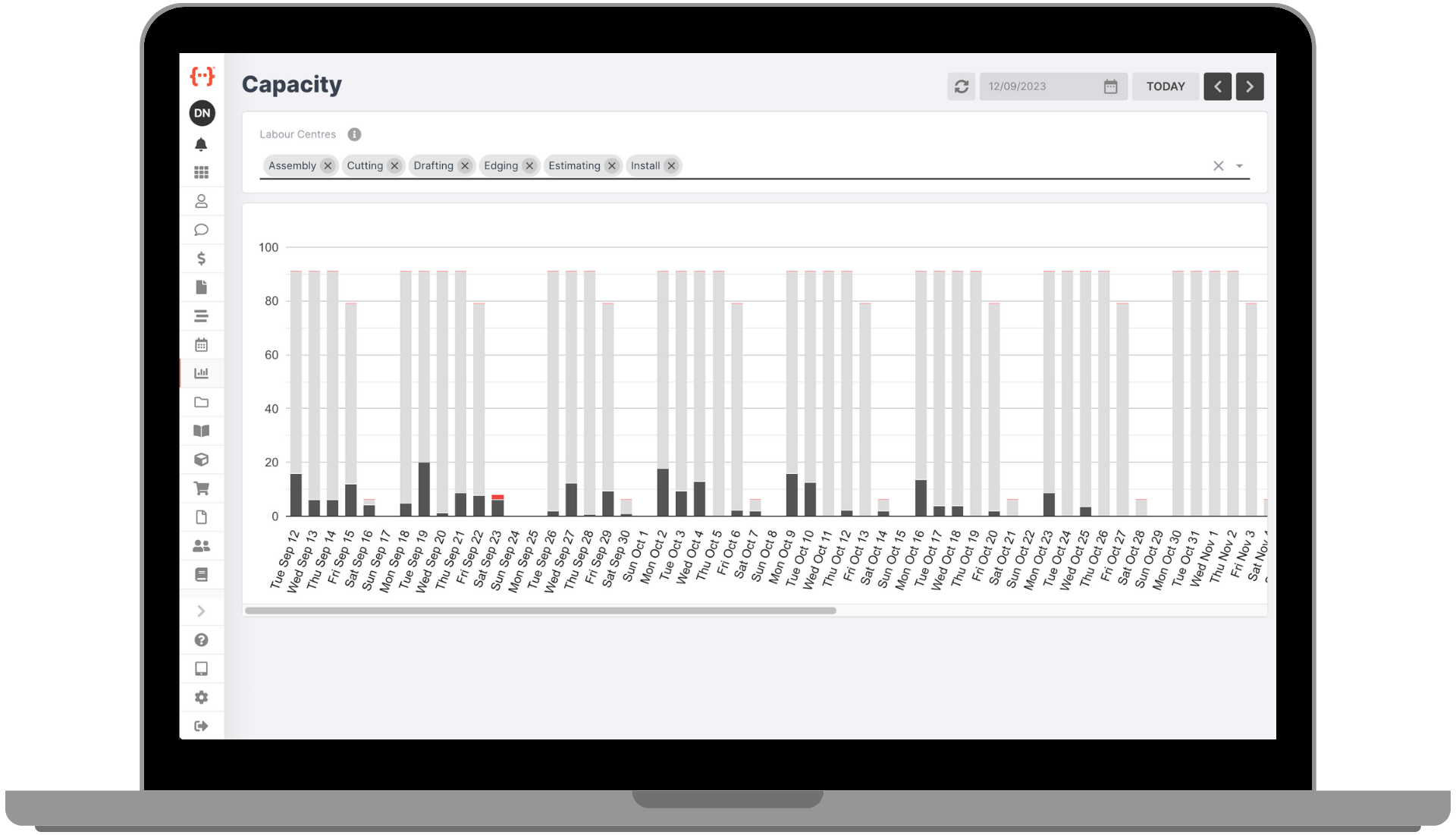

Use labour centres to set capacity limits

Jobman automatically assigns jobs based on your predefined labour centres. In every labour centre – for example, an operator, design team or machine – you can set specific operations and how many hours that labour centre has available.

Let’s say you have a multi-skilled operator who can work a shaper, CNC router and belt sander. When a new job comes in, you can assign work to that person based on how much free time they have alongside other jobs.

That means you can optimise capacity without overloading a resource. And you can rearrange jobs to schedule similar jobs together, reducing wasted time and shortening production timelines.

Simplified overview

Jobman’s user-friendly screens make capacity planning as easy as dragging and dropping jobs. All your upcoming work appears in a calendar overview, with flexible view options to show overlapping workstreams.

Because Jobman is ERP Software for manufacturers and cabinetmakers, the features are customised for busy operations. For example, you can filter the capacity view to show drafting and production simultaneously, making sure jobs can flow from one stage to the next without delay.

Improve productivity & reduce costs with Jobman

Jobman provides an end-to-end overview of your entire operation. Capacity planning is only one piece of the puzzle; to win new work, you need to know your inventory, logistics, production, and workforce are under control.

This is where a simplified ERP with capacity planning software for manufacturers is invaluable. Jobman works hard behind the scenes to combine all that operational data, so when you plan capacity into the future, you’re never caught out.

Data-driven automation frees up hours for busy manufacturers and cabinetmakers. Now you can focus on growing your business in the right direction and investing in new products and equipment.