Creating a culture of data-driven insight in Australian manufacturing

ERP software benefits manufacturers of all sizes by combining operational data from across the value chain into a single user-friendly interface.

Software can inform more intelligent decisions, but it can’t replace human intuition.

Successful management teams know this difference. According to Deloitte, 49% of businesses use analytics to drive better decision-making, and another 16% leverage analytics to inform long-term strategic initiatives.

Leading manufacturers rely on a combination of ERP data, analytics, experience and feedback to grow their operations. So let’s investigate how ERP software helps you stay informed, stay focused, and continuously improve productivity.

Gathering insights into one place

The market moves faster today than ever before. With so much competition springing up, and innovation occurring at lightspeed, you don’t have time to go hunting for accurate data.

Real-time data, sourced from every part of your business and

brought together into a single source of truth, enables you to make decisions

that maintain your competitive edge. Your ERP should deliver that insight to

your entire team.

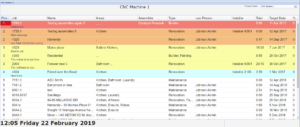

Jobman, for example, provides real-time production data so your team can track progress on current and upcoming jobs. You can make production decisions from these intelligent agenda screens resulting in short-term cost savings, long-term process improvements, and early issue identification.

Jobman’s Agenda Screens

Enabling cost-cutting without compromising on quality

We recently published an article about ERP and cost control. ERP software enables management and accounting teams to collaborate on cost-cutting activity by making production costs more transparent.

One frequent benefit of using a manufacturing ERP is identifying hidden costs. Those are the indirect costs that aren’t easily seen on a cashflow report but instead turn up in the form of production bottlenecks, recurring defects and wasted resources.

Of course, the ERP can’t tell you which activities or materials to cull. Instead, it shows the true cost of every activity throughout the production process, delivering the insight you need to set priorities and incrementally reduce costs.

Nurturing high-value customers

Jobman’s CRM (customer relationship management) functionality is another instance of using data to make strategic decisions. Integrating CRM and ERP enables a 360-degree view of the customer lifecycle, so you can choose to invest in growing key accounts or going after a particular type of high-value customer.

ERP-CRM integration opens up more sales opportunities by giving your sales team the data they need to make better, faster decisions. For example, Jobman enables on-the-spot quoting and even automates much of the lead nurturing process.

Management can generate sales reports whenever they like, see a customer’s entire transaction history, forecast peaks and troughs in demand, and choose to proactively follow up with high-value customers.

Collaboration is key

ERP software is a cross-organisational tool; that means your entire team is working from the same centralised data. So while all the above benefits lead to process improvements in their own right, the overarching benefit of an ERP like Jobman is to encourage a culture of continuous improvement.

Even minor improvements can contribute to growing your manufacturing business. When your team has access to a huge range of real-time data from a trusted source, real-time collaboration and real-time productivity improvements become a reality.

Get started today by contacting Jobman for a no-obligation consultation.